Total (Formerly Maersk) | Culzean Field Development

With facilities spread across 3 bridge-linked platforms, and condensate storage via an FSO, the Culzean field development featured numerous ex...

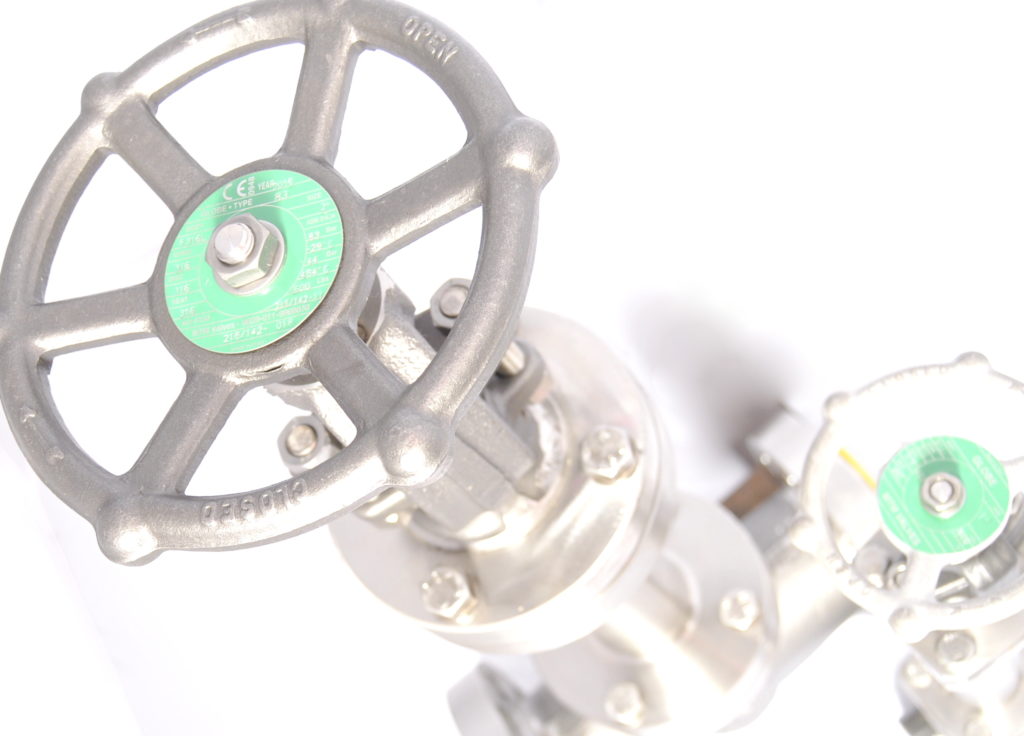

Carbon steels (LTCS and High yield) Stainless Steel

Duplex/Super Duplex

Ni-Al Brz

Inconel, Titanium and other exotics

According to your project specifications

PMI

MPE

DPI/LPE

Radiography/UT testing

Ferrite testing and IGC to ASTM A262

Specialist bolting (enhanced NDT, Xylan coated etc) Garlock ESVP 9000 packing

Operators in stainless steel

Non-graphite fire-safe seals available