Special Products

Product overview

In addition to our broad portfolio of standard valve types engineered to meet your project needs, PJ Valves offers a range of special valve solutions.

Whether your challenge involves proving material suitability for an application or altering valve configurations and dimensions outside of standard norms, PJ Valves is your ideal partner to translate concept development into high performance products.

Whether your challenge involves proving material suitability for an application or altering valve configurations and dimensions outside of standard norms, PJ Valves is your ideal partner to translate concept development into high performance products.

Production range

Founded on our in-depth knowledge of applicable industry standards, and our in-group engineering ability, we have the skills and experience to solve your valve design challenges.

Range

Material scope

PJ Valves believes that every good valve starts with quality raw materials. We are experts in compliance with stringent material specifications including NORSOK, and a wide variety of end user requirements covering both metallic and non-metallic parts.

Increasingly, severe upstream operating conditions mean specifications focus not only on primary valve components, but also elements such as bolting and operator materials. PJ Valves can meet the needs of any project specification through established relationships with our component supply chain.

Increasingly, severe upstream operating conditions mean specifications focus not only on primary valve components, but also elements such as bolting and operator materials. PJ Valves can meet the needs of any project specification through established relationships with our component supply chain.

Carbon steels (LTCS and high yield)

Stainless steel

Duplex/super duplex

Ni-Al Brz

Inconel, titanium and other exotics

According to your project specifications

PMI

MPE

DPI/LPE

Radiography/UT testing

Ferrite testing and IGC to ASTM A262

Specialist bolting (enhanced NDT, Xylan coated etc)

Wide range of specialist seal material options

Specialist metallic coatings for valve trim parts

Features and options

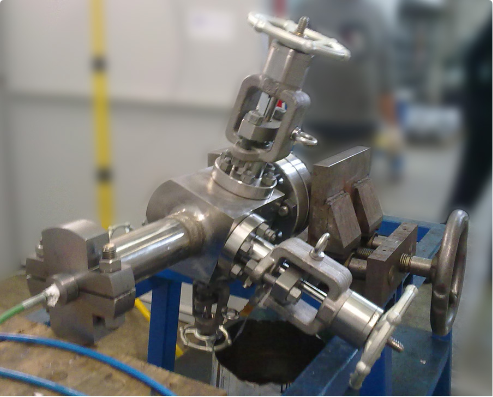

A wide range of special product types are available, with all the engineered feature options that are also available on our wider valve production range.

Perhaps you need something so special that it hasn't been developed yet? Our experienced valve designers work in partnership with you to develop valve design solutions based on specific application or process needs.

Perhaps you need something so special that it hasn't been developed yet? Our experienced valve designers work in partnership with you to develop valve design solutions based on specific application or process needs.

Special product examples

Would you like to find out more?

Relevant applications

Mooring applications call for a diverse

range of products with common features in specification and configuration.

High pressures, metal seating and

corrosion resistant alloy materials are typical requirements.

range of products with common features in specification and configuration.

High pressures, metal seating and

corrosion resistant alloy materials are typical requirements.

The Angelin development, originally discovered by the El Diablo well in 1995, includes a new platform and four wells. It is located 60 kilomet...