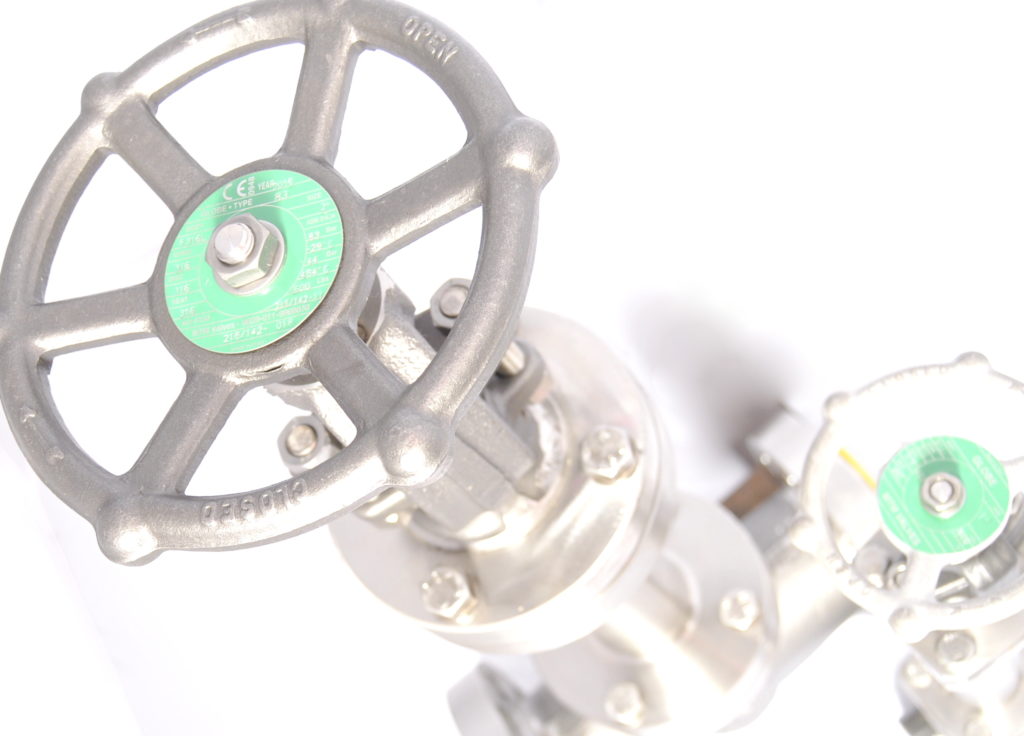

PJ Valves celebrates new factory expansion in Pune, India, marking a milestone in growth and innovation

Hertford, UK January 2023: PJ Valves celebrates new factory expansion in Pune, India, marking a milestone in growth and innovation.

Scope change support

We developed and implemented an improved documentation process